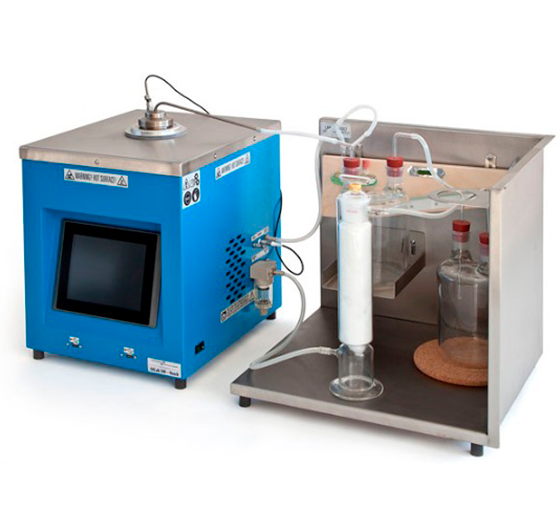

Descripción

Measuring Parameters

- Temperatures: in °C

- Testing range: +225°C to +275°C

- Measuring range: 0°C … +320°C

- Resolution: 0.01 °C

- Accuracy: ± 0.1 °C

- Repeatability / Reproducibility: according ASTM D5800

Features:

Differential pressure 20 mm H20, accuracy 1%

Same dimensions and volume as ASTM D5800

Electrically heated new designed aluminium block, no Woods metal needing

Electrical resistance, 500 W

Equipped with high resistant Kalrez valve, inlet filter to remove product residuals

Automatic electronic control system able to maintain the -2mB during the analysis

Low voltage power supply

TFT/LCD 8”

Resolution 1024 × 768, 16.2 M colours

2 USB ports for connection to an external printer and/or external PC

Storage capacity for more than 60’000 analysis

Lin-Tech operating software Lab-Link running in Windows ambient

Automatic reading of the weight suggested balance LT/B-2470/BCA500 INT- CAL

Customizable results report

Printable graphs and results